Manufacturing

We have been in business for over 40 years, offering a wide range of products. With over 8,000 formulations in house, we are one stop shop for Tablets, Capsules, Softgels, Powders and OTC's. Vitamins for Life holds a Drug and Medical device manufacturing license as well as Dietary Supplements & Cosmetics.

Tableting and Encapsulation

Tablets, Chewables, Capsules and Softgels can be manufactured for our customers with our existing or custom formulations. We have the capability to do color, enteric and sugar coatings. Our automatic rotating tablet presses and high speed encapsulation machines can produce millions of different products, conforming to the highest standards for accuracy and efficiency.

Packaging

We can offer a full range of packaging, Bottles, Canisters and Blisters. We have several different types of packaging options available to satisfy our customers.

Contract Services

Tableting, Encapsulation, Powders, Blending, Granulation, Coating, Packaging, Custom Formulations, Research & Development, Technical Services

Manufacturing Specialties

Tablets, Time Release, Bi-Layer and Tri-Layer Tablets, Chewable Tablets, Capsules, Softgels & Powders.

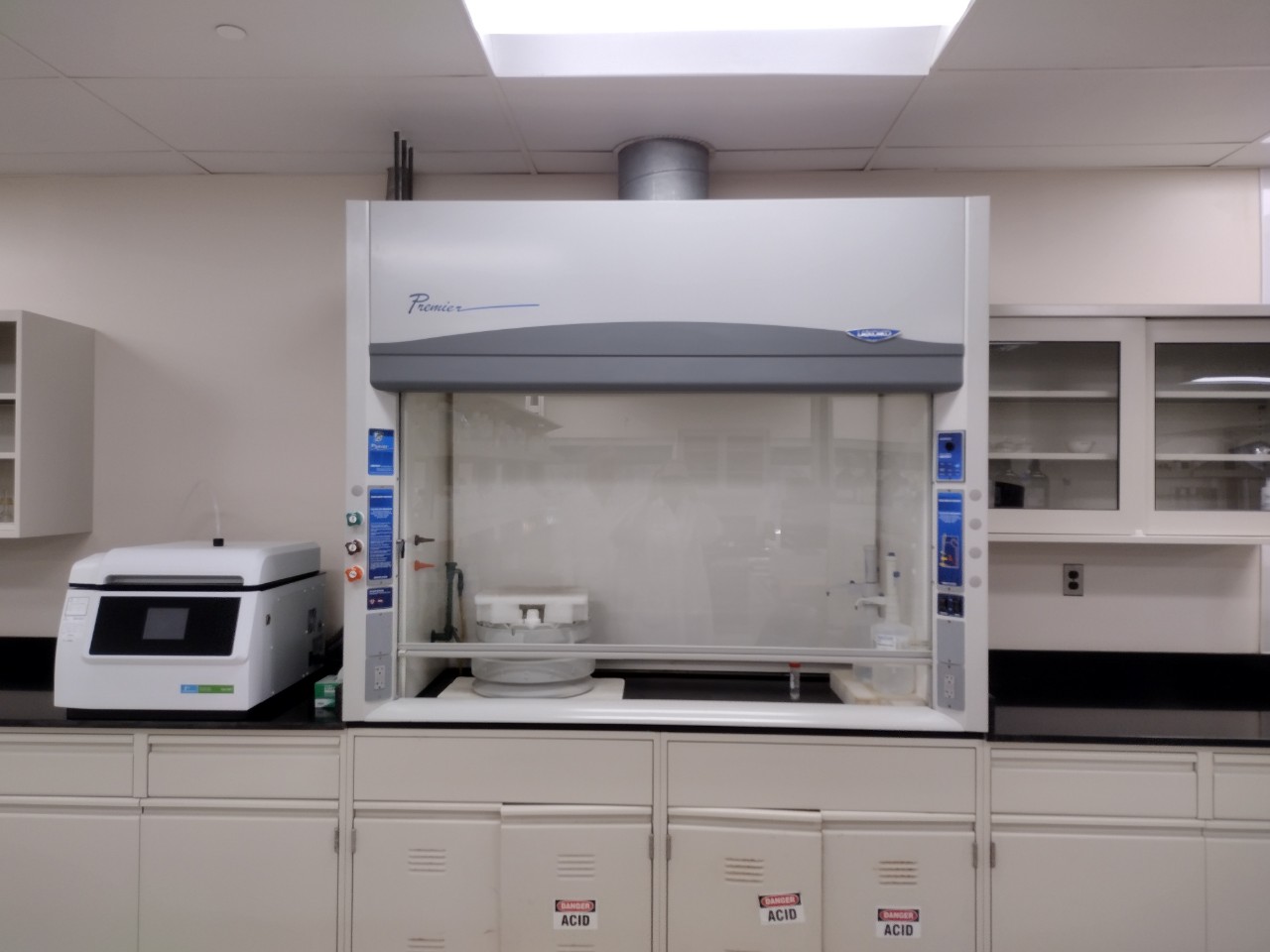

In-process testing is performed by Quality Control to determine whether the product being manufactured conforms to all specifications. Physical testing is performed during manufacturing and before release of the finished product, while assaying of products actives and inactives is performed by our analytical laboratory, as per set specifications and customer's requirements. A Certificate of Analysis is provided to the customer for all products manufactured. Samples of raw materials and finished products are retained under control conditions for at least three years past the expiration date of the product. Stability studies are performed to assure the highest quality possible of our formulations.

Quality Control

Specifications, standards, testing and operating procedures are drafted by the respective department and approved by the Director of Quality Control and Assurance. Controls include the establishment of specifications for raw materials, components and finished products. All materials go through testing procedures to assure product identity, quality, strength and purity. The Director of QA also maintains calibration records of all instruments and, in addition, checks for conformance of all operations to the set procedures. Our facility operates under cGMP Guidelines of USP (United States Pharmacopeia), European Pharmacopeia and Chinese Medicine.